Polo Mk5

Note

Note

|

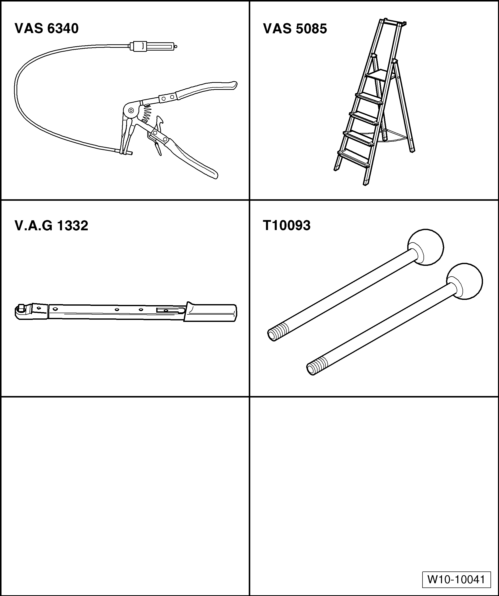

| Special tools and workshop equipment required |

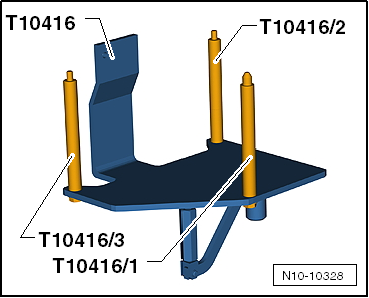

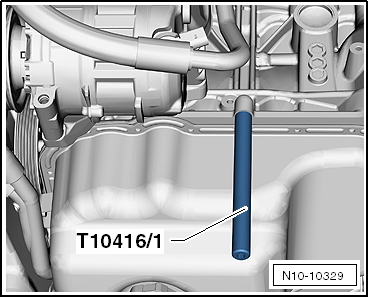

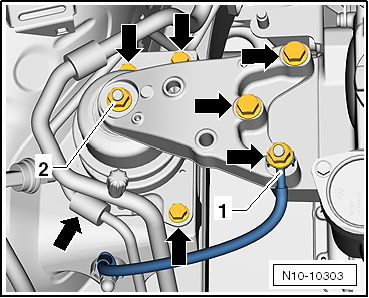

| t | Engine support -T10416- with adapters /1, /2, /3 |

| t | Torque wrench -V.A.G 1331- |

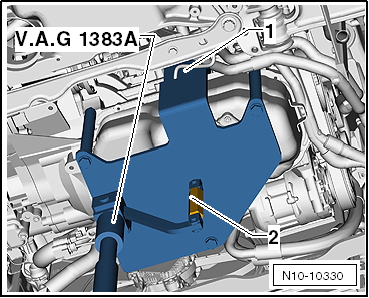

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Engine and gearbox support -VAS 6095- |

| t | Drip tray for workshop hoist -VAS 6208- |

| t | Hose clip pliers -VAS 6340- |

| t | Stepladder -VAS 5085- |

| t | Torque wrench (40 … 200 Nm) -V.A.G. 1332- |

| t | Guide rods -T10093- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

WARNING

WARNING Caution

Caution