Polo Mk5

| Removing and installing suspension strut |

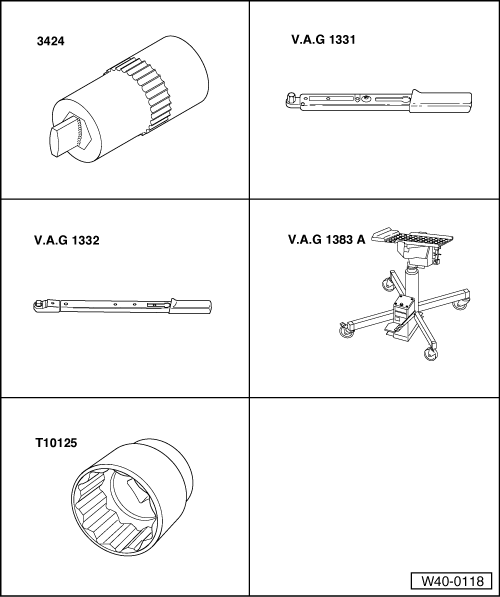

| Special tools and workshop equipment required |

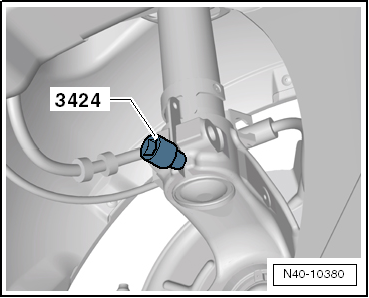

| t | Spreader -3424- |

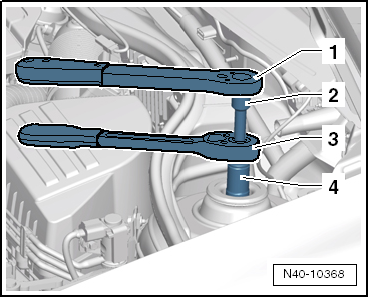

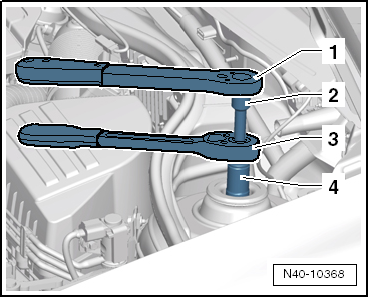

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

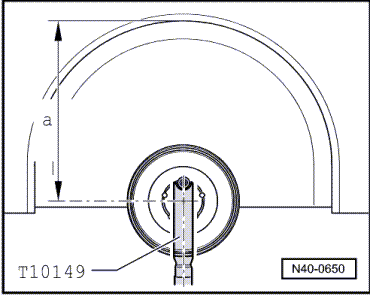

| t | Socket (36 mm) -T10125- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

| Specified torques |

| Component | Specified torque | ||

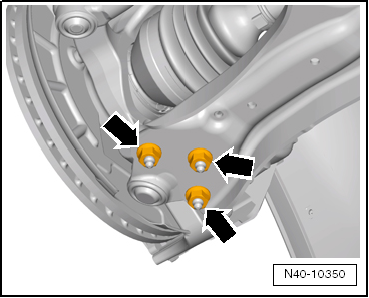

Suspension strut to body

| 60 Nm | ||

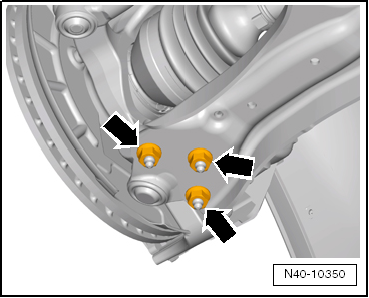

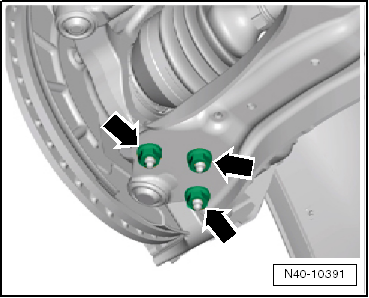

Suspension strut to wheel bearing housing

| 60 Nm + 90° | ||

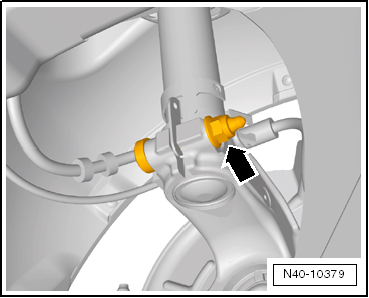

Swivel joint to suspension link

| 100 Nm | ||

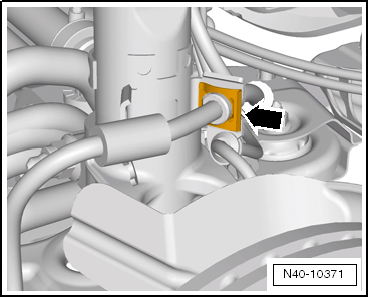

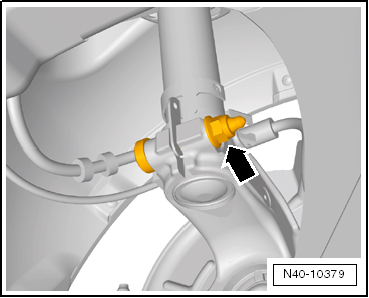

| Coupling rod to suspension strut

| 40 Nm | ||

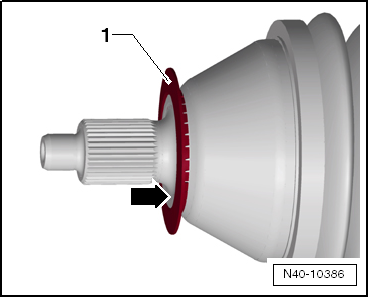

12-point nut on drive shaft

| 50 Nm + 45° |

Caution

Caution WARNING

WARNING