Polo Mk3

|

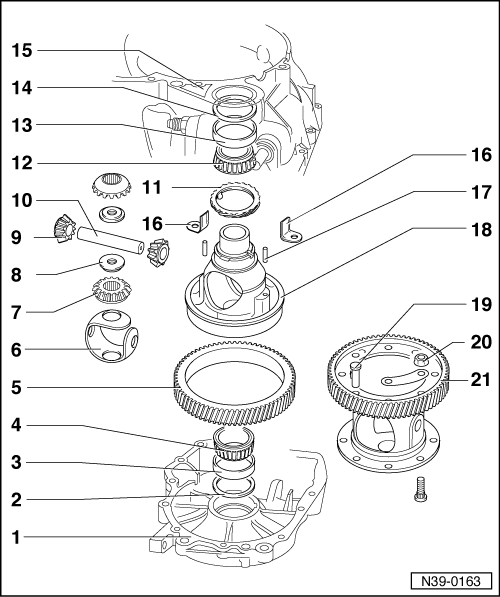

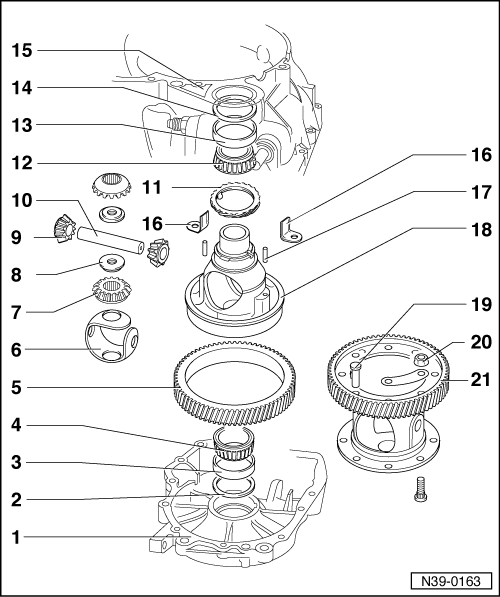

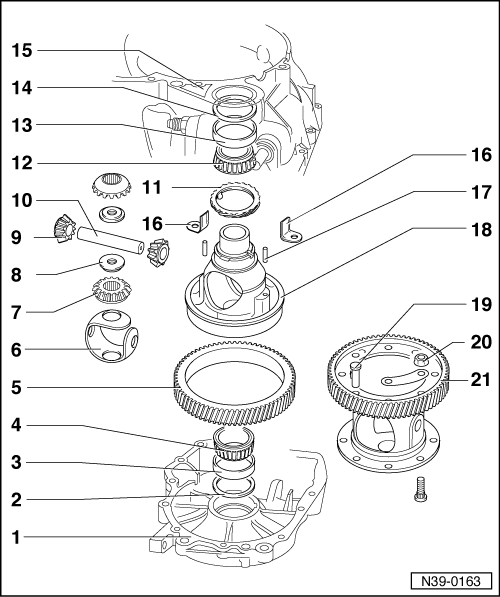

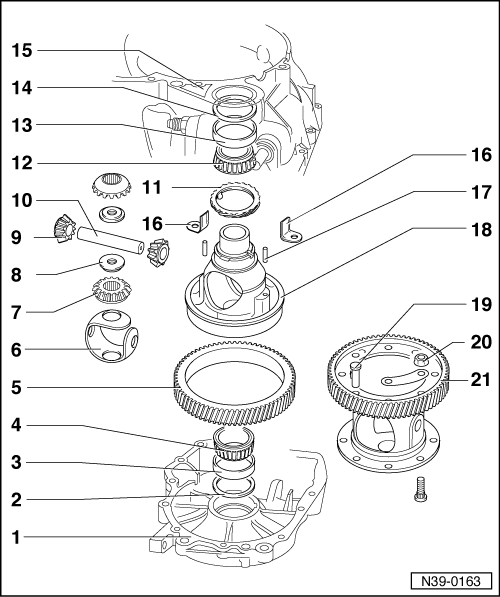

Dismantling and assembling differential

Dismantling and assembling differential

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

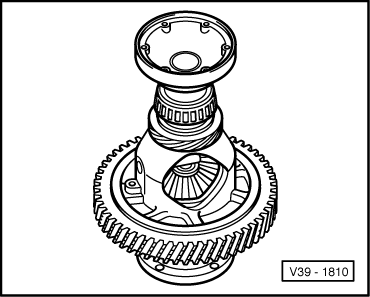

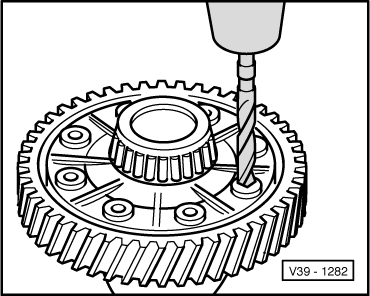

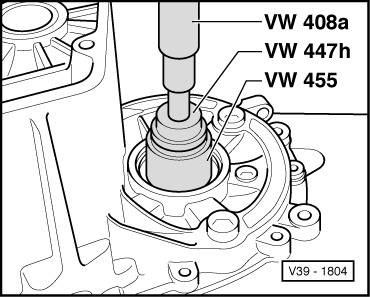

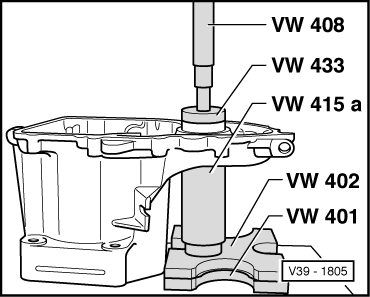

→ Fig.1 Pressing out taper roller bearing outer race |

|

|

|

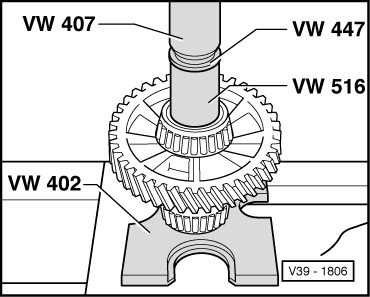

→ Fig.2 Pressing in taper roller bearing outer race |

|

|

|

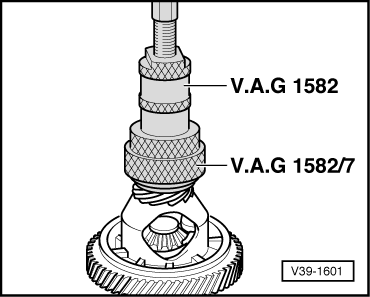

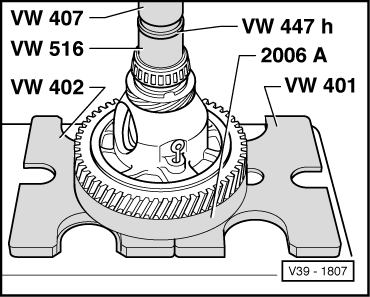

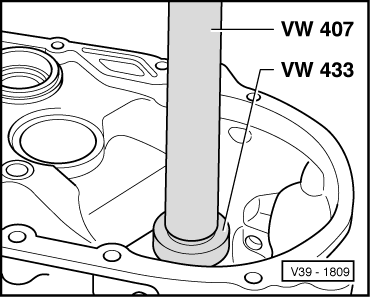

→ Fig.4 Pressing on taper roller bearing inner race

|

|

|

|

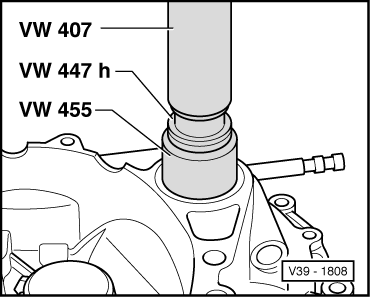

→ Fig.6 Pressing on taper roller bearing inner race

|

|

|

|

→ Fig.7 Pressing out taper roller bearing outer race |

|

|

|

→ Fig.8 Pressing in taper roller bearing outer race |

|

|

|

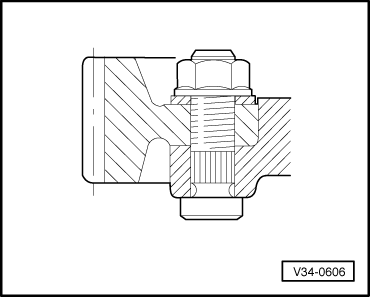

→ Fig.10 Assemble gear wheel and differential housing using special bolts, plates and nuts |