| –

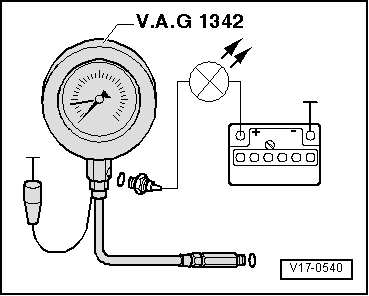

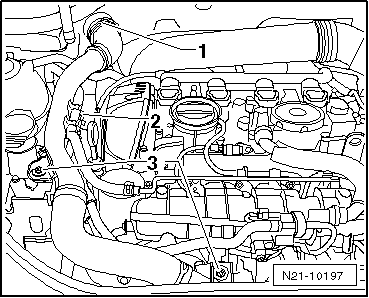

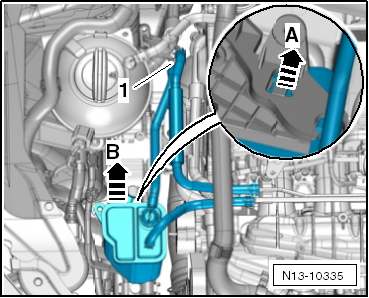

| Connect brown wire of tester to earth (-). |

| –

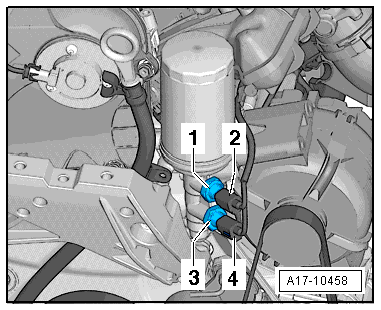

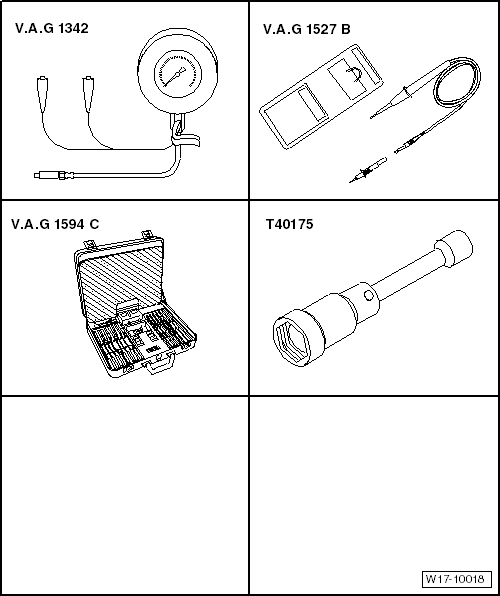

| Connect voltage tester -V.A.G 1527B- to battery positive (+) and oil pressure switch for reduced oil pressure -F378- (brown) using cables from auxiliary test set -V.A.G 1594C-. |

| –

| If LED lights up, replace oil pressure switch for reduced oil pressure -F378-. |

| If LED does not light up: |

| –

| Start engine. At 0.55…0.85 bar, the LED must light up, otherwise renew oil pressure switch. |

| Checking oil pressure switch -F22- (blue): |

| –

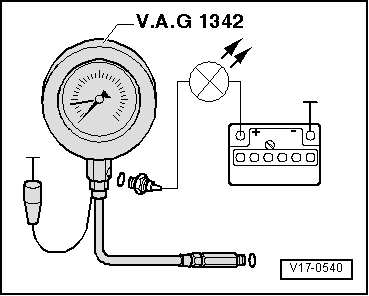

| Connect voltage tester -V.A.G 1527B- to battery positive (+) and oil pressure switch -F22- (blue) using cables from auxiliary test set -V.A.G 1594C-. |

| –

| If LED lights up, replace pressure switch -F22-. |

| If LED does not light up: |

| –

| Start engine and increase engine speed. At 2.15…2.95 bar, the LED must light up, otherwise renew oil pressure switch. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note