| –

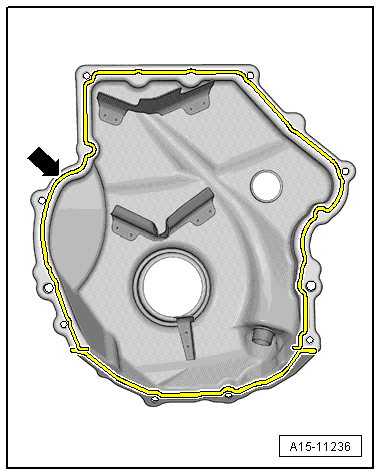

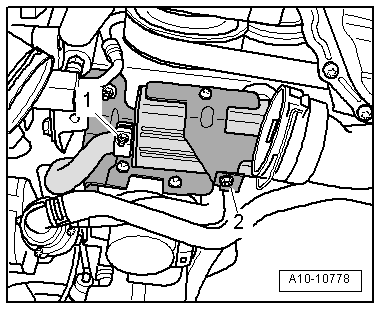

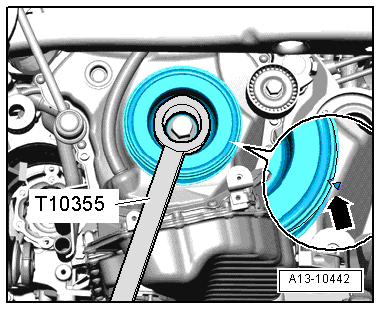

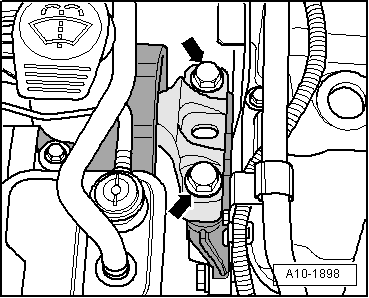

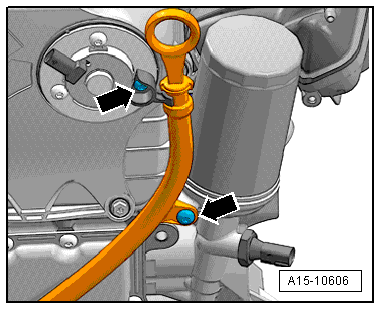

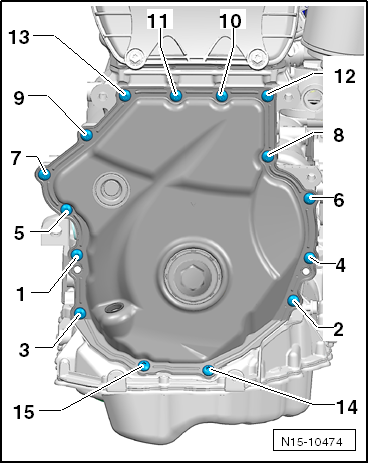

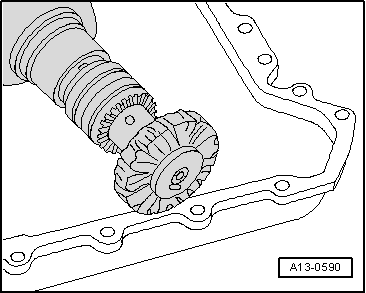

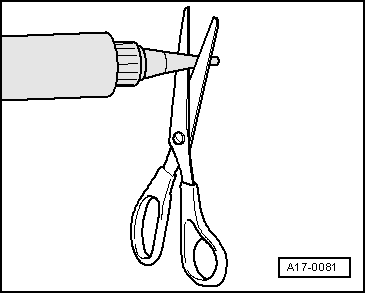

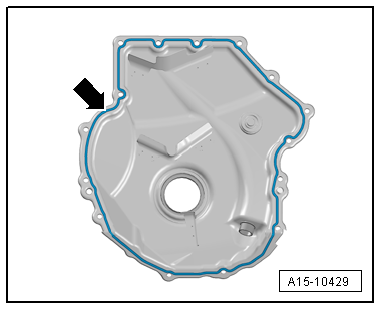

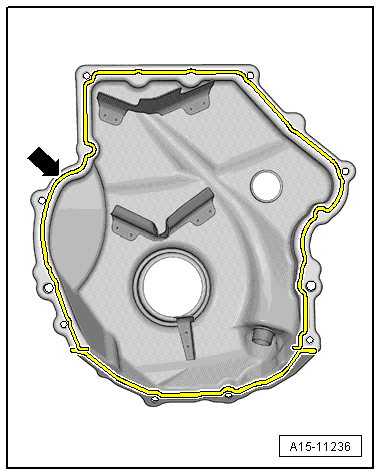

| Apply silicone sealant -D 174 003 A2- onto clean sealing surface of new cover, as shown in illustration. |

| t

| Thickness of sealant bead: 2 ... 3 mm |

Note | t

| The cover must be installed within 5 minutes after applying the silicone sealant. |

| t

| The bead of sealant must not be thicker than specified, otherwise excess sealant can enter the sump and obstruct the strainer in the oil intake pipe. |

| –

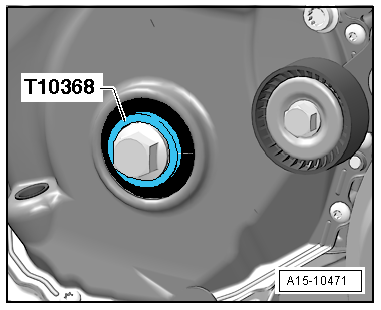

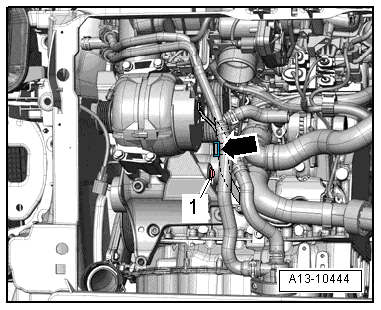

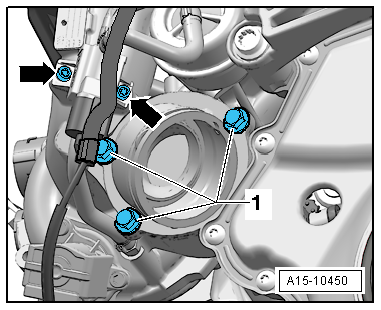

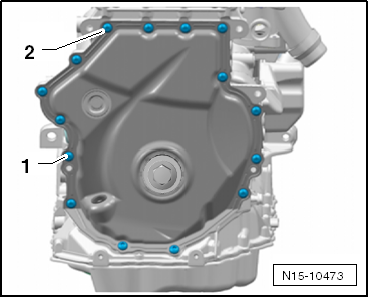

| Install cover immediately and tighten bolts: |

Note | After fitting cover, let sealant dry for approx. 30 minutes. Only then fill with engine oil. |

| –

| Fill up with engine oil. |

| Further assembly is basically the reverse of the dismantling sequence. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution WARNING

WARNING