Golf Mk3

|

|

|

|

|

|

|

|

|

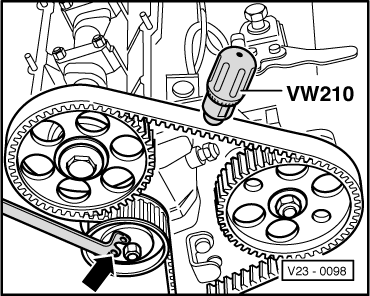

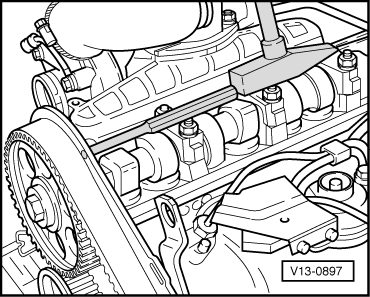

Note: Never use setting bar as a counter hold when loosening and tightening the camshaft sprocket, use retainer 3036.

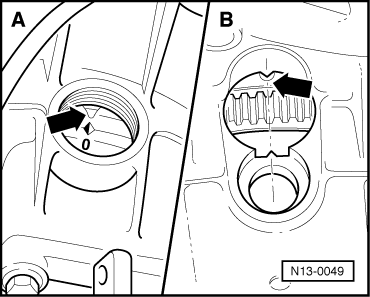

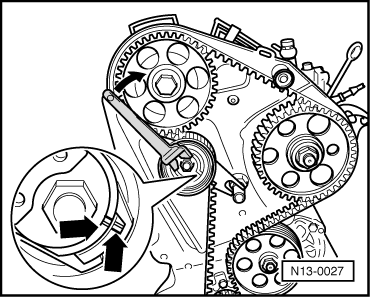

Engines without semi-automatic tensioning roller: |

|

|

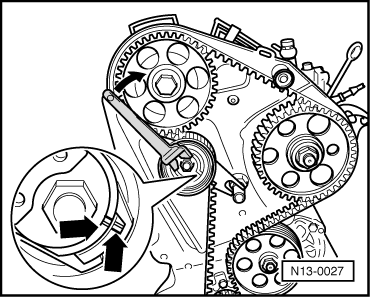

Engines with semi-automatic tensioning roller:

|

|

|

Note: If the eccentric has been turned too far the tensioning roller must be relieved completely and retensioned. The eccentric must never be turned back when it has been turned too far.

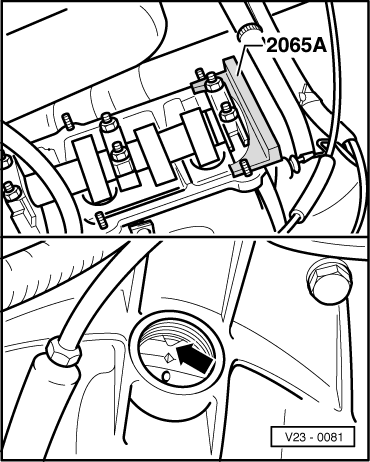

Continuation for all engines

Engine codes 1Z, AHU, AEY, AFN, AVG, ALE

Engine codes 1Y, AAZ

|

|

|

|

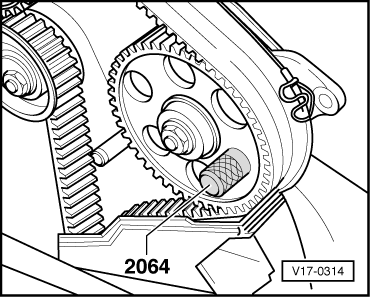

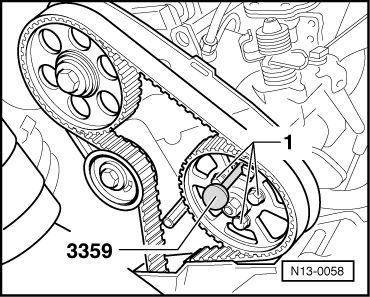

Belt drive with two part injection pump sprocket Removing

|

|

|

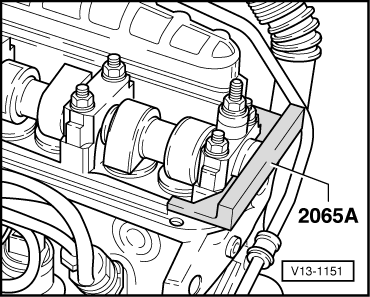

Installing

Note: Never use setting bar as a counter hold when loosening and tightening the camshaft sprocket, use retainer 3036. |

|

|

|

|

|

Note: If the eccentric has been turned too far the tensioning roller must be relieved completely and retensioned. The eccentric must never be turned back when it has been turned too far.

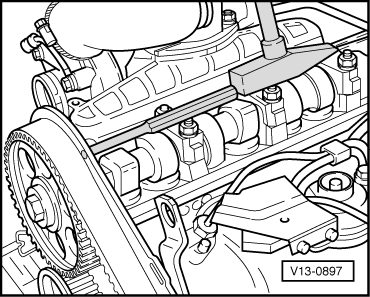

|

|

|

|

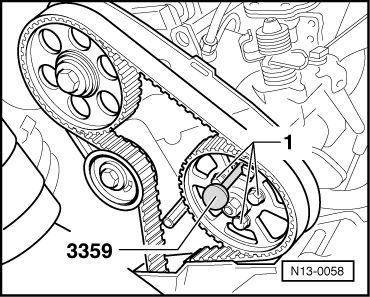

→ If the injection pump sprocket cannot be locked with pin 3359:

|