Golf Mk3

|

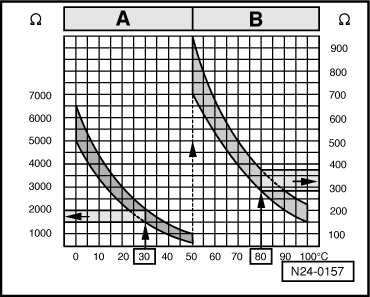

Mono-Motronic injection and ignition system

Servicing injection unit

|

|

|

|

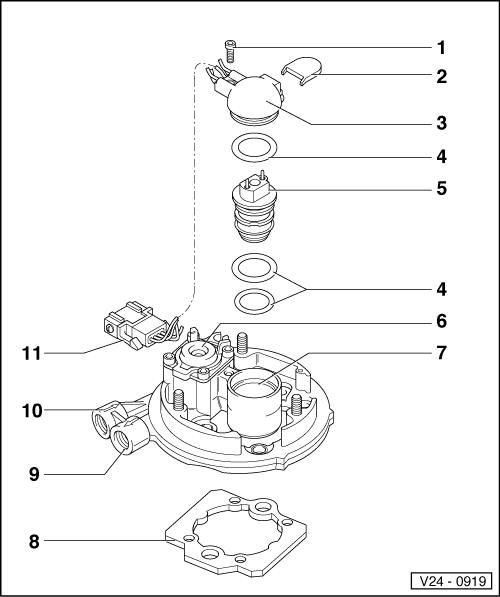

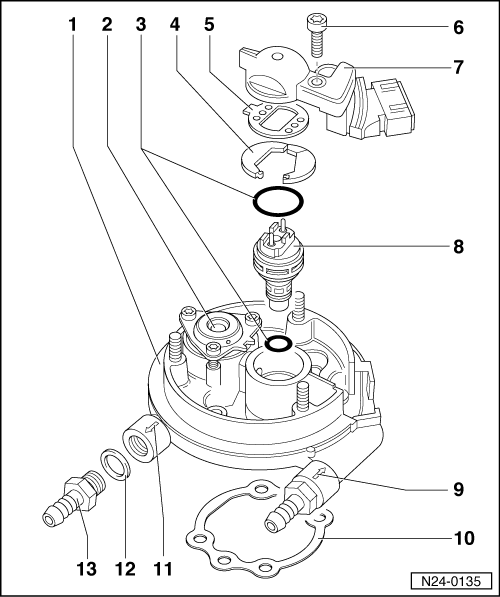

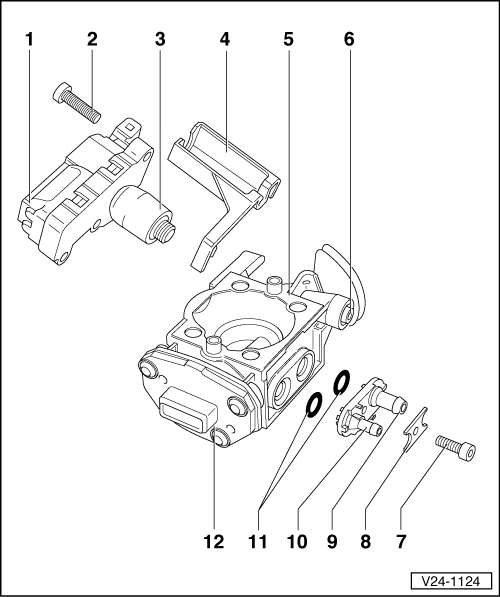

Engine code ABD Servicing upper part

|

|

|

|

|

|

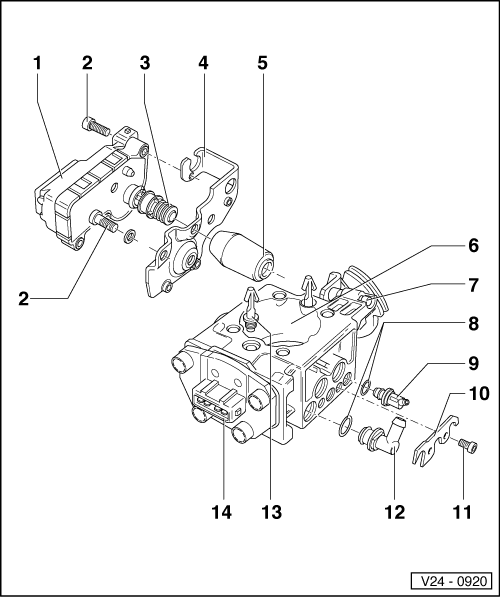

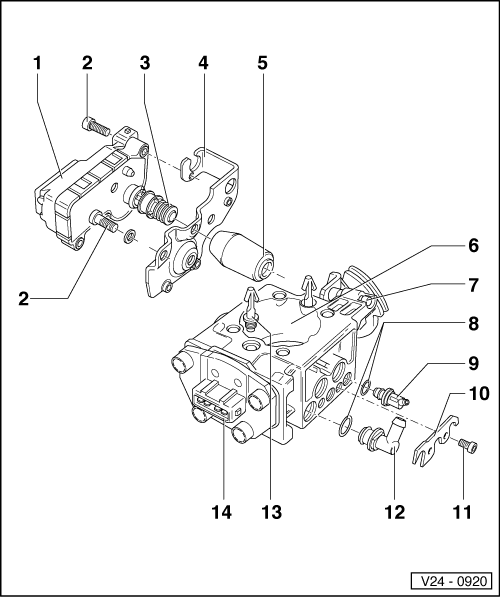

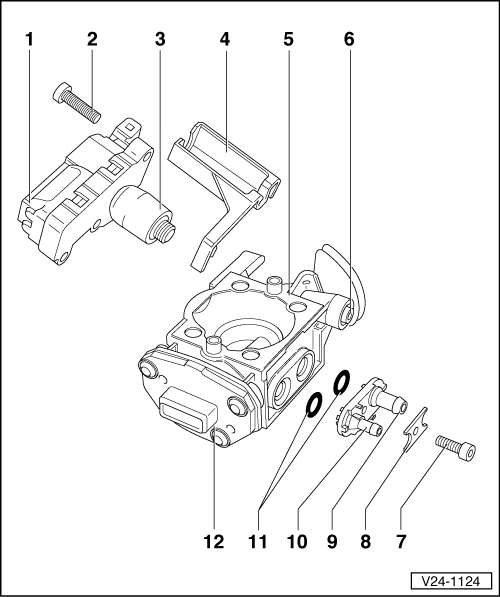

Servicing lower part

|

|

|

|

|

|

|

|

|

|

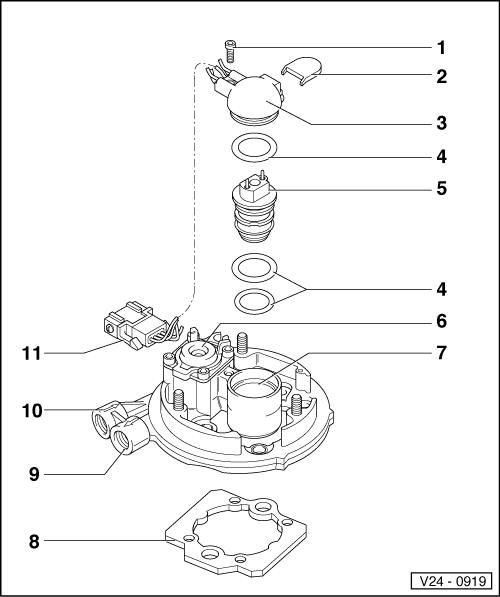

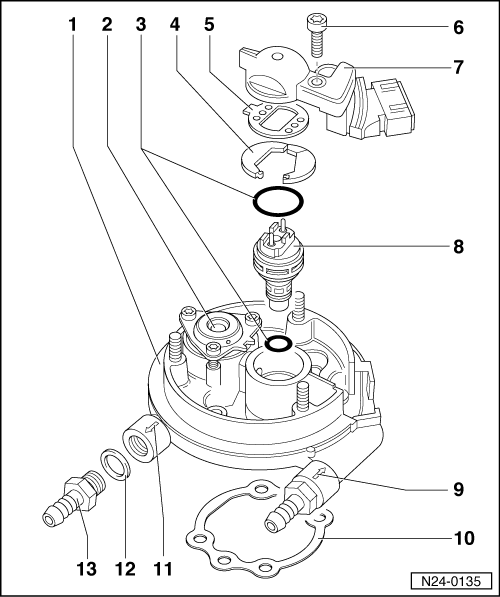

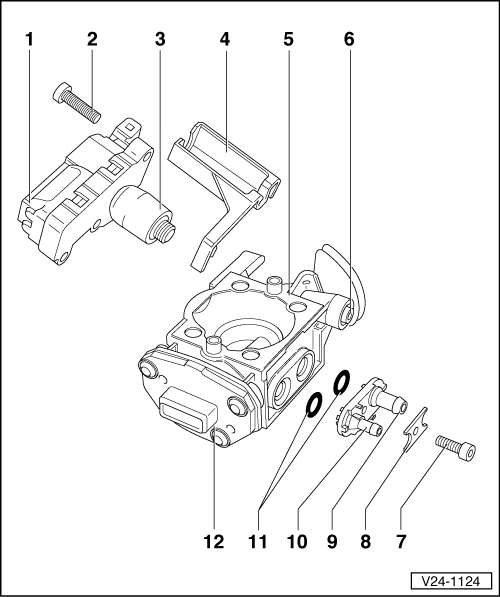

Engine code ABU, AEA Servicing upper part

|

|

|

|

|

|

|

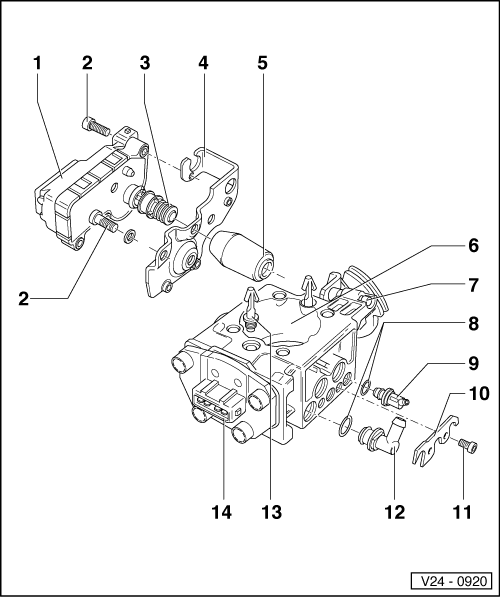

Servicing lower part

|

|

|

|

|

|

|